Our Services

ADVANCED SAND CONTROL TECHNOLOGIES

3M CERAMIC SAND SCREEN

Sand Screen manufactured direct from Sand, SiC

WHY CERAMICS?

Ceramics have -

- Outstanding hardness, almost as hard as diamond

- Exceptional Resistance to Wear

- Universal Corrosion Resistance

- Extreme Temperature Range -196⁰C to 1800⁰C

- Assures Completion Longevity

- Reduces Completion Complexity

- Prevents Hot spotting

- Can be run across Perforation

- Replaces Gravel Packs

- Reduces Well Intervention Needs

- Simple and easy to deploy

- Deployed using Slickline, E-Line, Coil Tubing or Drill Pipe

- Maximizes Production while saving cost.

APPLICATION

3M Ceramic Sand Screen has been run in different locations

globally where there are sand control challenges or to simplify

and make the completion cost effective.

3M Ceramic Sand Screen has been used successfully in -

- Oil & Gas Well applications

- New Well and in Rigless Well Intervention

- Reservoirs with high erosive sand with high flux velocities

HIGH EXPANSION MECHANICAL PLUGS, HEMP

Low Cost/High Success Rate. Thru' Tubing Intervention Technology

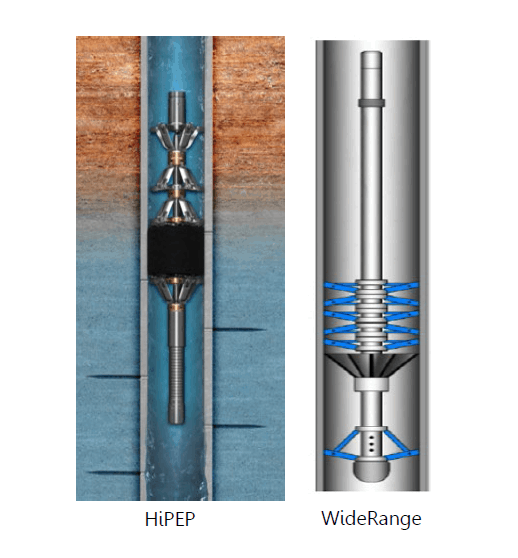

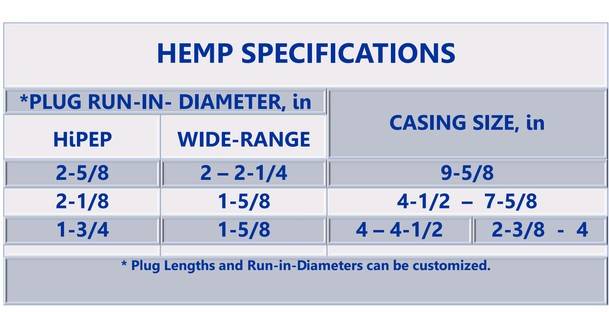

HEM Plugs come in two models - Retrievable (HiPEP) and Non-Retrievable (WideRange)

HEM Plugs can pass thru small restrictions and set in casing and open-hole diameters

over 3½ times their run-in diameter. Each HEM Plug sets in a wide range of casing sizes.

HEM Plugs can be run and set on Wire line, Slickline, and Coiled Tubing. HiPEP retrieval

can be done on Wire line or slickline. Wide-Range can be milled off, when required.

Success Rate - The estimated success rate for plug-back projects where vented HEM Plugs

are run on Wire Line and slickline is greater than 95%.

The combination of low cost and high success rates make thru-tubing plug-back

operations an economically attractive method of Well Intervention.

100% non-explosive isolation operations, using, non-explosive setting tool.

The HEM Plugs have been deployed in over 100 Well projects globally

APPLICATIONS

The HEMP tool from Calvante has been used by operators worldwide for:

- Rigless zonal isolations and recompletions

- Isolation of crossflow & thief zones

- Water production shut-off

- Wellhead repairs & replacements

- Tubing string repairs and replacements

- Temporal/Permanent P&A operations

SMARTJET PERFORATION SOLUTIONS

Abrasive Perforation System

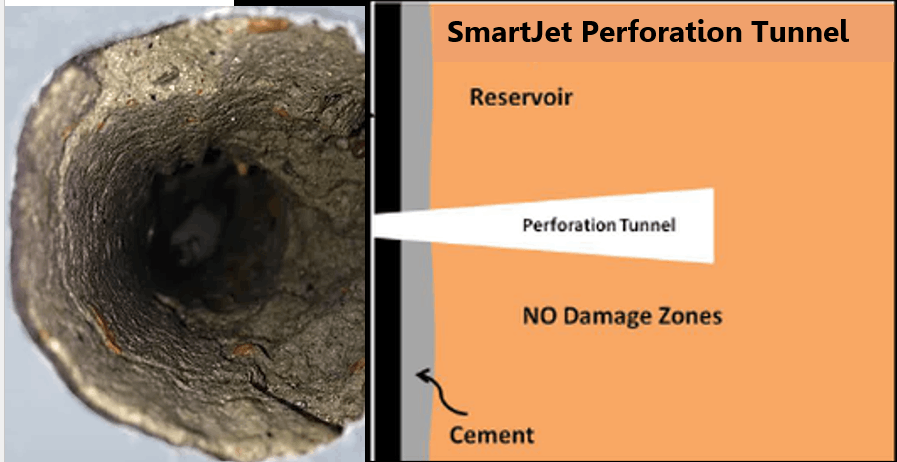

Here a slurry containing abrasive solids is pumped at

high differential pressures through the nozzle of the

specially designed SmartJet tool conveyed on a Coil Tubing

work-string. The resulting high-velocity fluid stream perforates

tubulars and any surrounding cement sheath,

providing a large perforation fluid tunnel.

Effective alternative to Gun Perforation

SmartJet Perforator does not require explosives. It provides a better

alternative to Wireline or tubing conveyed explosive Perforation.

The SmartJet Perforator provides perforations with no skin effect

or formation damage; therefore, breakdown pressures for fracture

initiation are reduced, leading to more effective stimulation treatments.

Features & benefits

- Eliminates need for explosive perforation.

- Can be run with jointed pipe or coiled tubing, enhancing operational flexibility.

- Multiple zone perforation can be achieved in one operation.

- Large debris free perforation fluid tunnel allows fluid flow with low pressure loss.

- Horizontal & Open hole application available

- Can penetrate multiple casing strings.

- Increases vertical permeability in horizontal applications provides additional production capability.

- Has no depth or temperature limitations, enabling operations in high-temperature, high-pressure (HTHP) environments.

- HSE and regulatory requirements.

- A more cost-effective reservoir perforation solution

CASING LANDING SOLUTIONS

Smart Casing Reamer

Patented Technology. Designed to provide rotation at the end of the casing string without applying rotation to the string. A low-cost improvement to operational efficiency. Smart Reamer has an impressive 99.2% success rate at landing the Liner Hanger and well completions to TD. Smart Reamer has been used successfully in over 750 projects, globally.

APPLICATIONS

- Ensure Casing string gets to TD.

- Navigates ledges, washouts, doglegs with ease.

- Ream tight spots from swelling shale and other geological issues.

Features

- PDC Drillable Components

- Not an Indexing Tool, provides 360deg rotation.

- Internals made from Industrial grade aluminum/bronze giving it strength & durability with fast drill out.

- Fast drill out significantly reduces drilling time inside casing thus protecting Bit, BHA and casing.

- Tool is Torque neutral, causing no torsional translation up the string.

- The Smart Reamer provides - circulation, agitation, and full rotation without rotating the Casing string. Standard shoes/Reamers do not provide full rotation.

- Not sensitive to Mud & LCM systems, unlike Turbine Tools.

- Available from 2 7/8” up to 20” casing sizes.

- Customization available.

- No changes required in BHA & no need to modify the well program.

TARGETED PROCUREMENT & SUPPLY SOLUTIONS

We support your projects with quality products from verified OEMs

at the most competitive prices.

The Hallmark of our procurement solutions -

- On time delivery.

- Rigorous OEM verification

- Increased profitability.

Our robust quality assurance process ensures –

- The right equipment are supplied

- Equipment meets relevant technical standards such as ISO9001.

- Zero defects on products supplied.

- Regulatory compliance

- Management of any non-conformance in a timely and professional manner

- Minimal disruption to supply chain.